réalisation d’une bague

Realization of a ring by rolling, welding and forging.

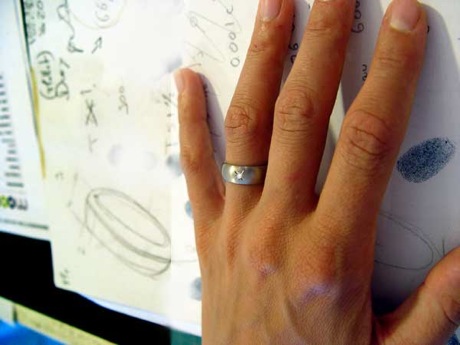

A ring in gold or silver can be made in the way described below, which means from a « wire » profiled, welded and forged. Below is an example among a multitude of shape variants (rounded, flat, concave, convex …) width, materials, theme etc … This precise example, is still set in a star of 5 diamonds, created as a wedding ring.

1° First the gold wire is rolled and forged to obtain the profile wanted

2° Once the profile of the future ring is there, the wire is cut to the exact length of the perimeter of the finger, then folded to make the two ends meet.

3° The two ends are adjusted perfectly against each other and the ring is then welded using an 18K gold having a melting point lower than gold which the ring is made with.

4° The now welded ring is forged on a cone (triboulet) to obtain a perfect circle. Then there is the filing, cleaning, finishing, then engraving with the stamp of the master and title of the metal, (the most common punches in Switzerland are 750 for 18K gold, 925 for silver)

5° On this ring, 5 diamonds were crimped as a « star » (we can see the basic sketches to make concrete proposals.)

Below: realization of the wedding ring for « him »

The ring below is made by using the technique of lost wax.

1° A wax is made to be used as a model for melting.

2° The ring will be an exact replica of the wax, therefore, the wax must be shaped carefully.

3° The wax was molded in a refractory material, then burnt, then the molten gold could then be injected and take the place of the empty space left by the wax.

Below we see the gold appear out of the mold that we break in order to extract the gold that took the shape of the wax model.

4° The gold ring begins to take shape as the molding material has been completely broken and the piece which the molten gold has passed through (casting cone) has been sawn.

5° After a fine cleaning, the white gold ring is cut in half, to allow a third rose gold ring to be welded between the two gray parts to create a pink color line.

6° The welding has been done on one half as the other side is still to be done. Then the welds will be file and then the ring will be totally finished by a fine sanding, to give it the appearance of « satin ».

8° The alliances united for the first time will be engraved again. You will find them engraved in the heading « creation of wedding rings ».

It is also possible to use the gold of your old jewelry to make a contemporary piece.

Click here to make your first inquiry for a personalized creation. Please give us the maximum of details of your desires, your expectations, your taste, and as well what kind of person you are etc … (this will allow us already to get to know each other, and we will answer you in both working days).

www.cbijoux.ch